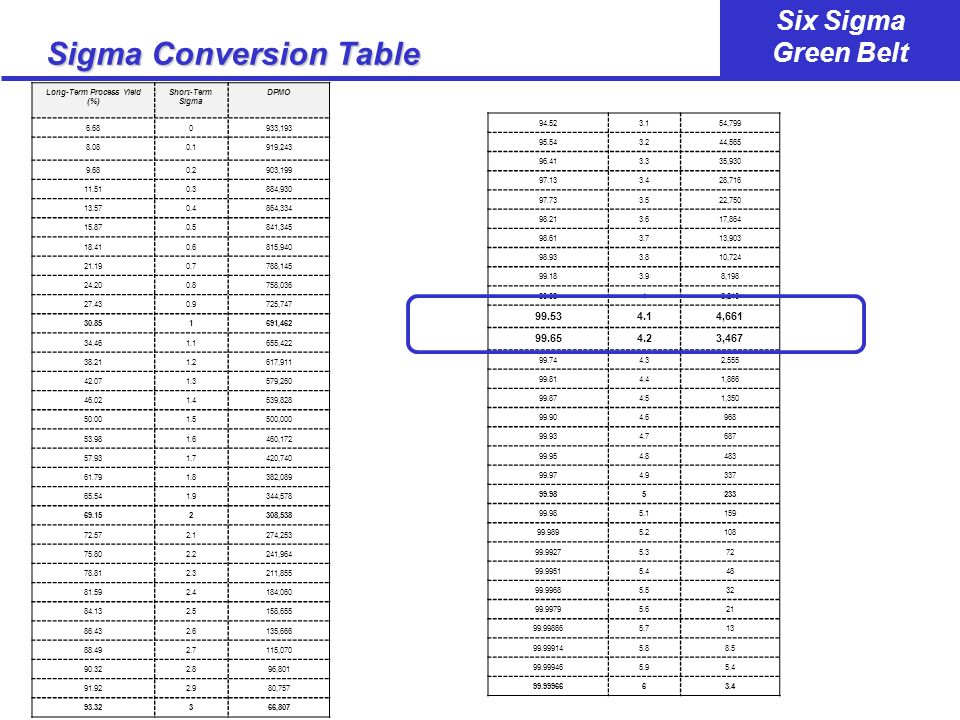

Sigma Conversion Table | Short term sigma conversion table. Particle size conversion table from our lab basics technical library. A sigma value is a statistical term otherwise known as a standard deviation. Dppm is often used when assessing the defect rate of a continuous material. Determining the standard deviation of a set of values helps a statistician or researcher to determine if the data set is significantly different than a control set. As for the upper index, we can decide that it must be 50 because we must have 2k = 100. Dppm conversion is most commonly used in manufacturing sector. 2k indicates an even number, which is a multiple of 2. A sigma value is a statistical term otherwise known as a standard deviation. Use the conversion chart to determine dpmo and sigma level. By convention established at motorola, where the six sigma program originated, the sigma level is adjusted by 1.5. Conversion process in an enterprise value chain. Determining the standard deviation of a set of values helps a statistician or researcher to determine if the data set is significantly different than a control set. Online sigma calculator for use in process control and quality assurance in industrial applications as well for overall business project management. Upon solving that equation, k = 50. Learn concepts, tools and methods in our free online knowledge center! When you've gathered your data and start making your calculations, be sure to keep these six sigma measures. In the above table, we have assumed that the standard sigma shift of 1.5 is appropriate (the process sigma calculator allows you to specify another value), the data is normally distributed, and the process is stable. Dppm is often used when assessing the defect rate of a continuous material. Use the conversion chart to determine dpmo and sigma level. A proportion defective of 1%. The following table will convert defects parts per million to a short term or long term process sigma level. The sigma level is one of the critical statistical terms of six sigma. Short term sigma conversion table. As for the upper index, we can decide that it must be 50 because we must have 2k = 100. The direct conversion between ppm and sigma (as in, not the six sigma conversion). A sigma value is a statistical term otherwise known as a standard deviation. In the above table, we have assumed that the standard sigma shift of 1.5 is appropriate (the process sigma calculator allows you to specify another value), the data is normally distributed, and the process is stable. A sigma value is a statistical term otherwise known as a standard deviation. Calculating baseline sigma is the first step toward understanding how well it's performing, and how much work will be required to achieve six sigma quality. Dppm is often used when assessing the defect rate of a continuous material. Short term sigma conversion table. To ensure that 2 is the first term, the lower index is clearly 1. Learn how to convert dpmo & sigma level from author six sigma handbook. Use this sigma calculator to easily calculate process sigma level, defects per million opportunities (dpmo, ppm), yield, rolled throughput yield (rty). The following table lists defects per million opportunities with the corresponding sigma level. A process that meets six sigma standards allows 3.4 defects per one million opportunities. Once you have the dpmo figures handy, you can refer to the sigma conversion table or a sigma level calculator to get the corresponding sigma level. So what is a sigma conversion table? Generally, you would use a table, such as provided in my six sigma demystified book, or you can calculate sigma level directly in excel using. 2k indicates an even number, which is a multiple of 2. Upon solving that equation, k = 50. So, as is typical in engineering, we assume that our process errors are going operating under that assumption, the direct conversion between ppm and sigma is pretty straightforward. Many people ask how percents and fractions convert to parts per million (ppm). As for the upper index, we can decide that it must be 50 because we must have 2k = 100. Sigma is a measurement of variability. Dppm is often used when assessing the defect rate of a continuous material. * the table assumes a 1.5 sigma shift because processes tend to exhibit instability of that magnitude over time. Use sigma notation to indicate these sums. It is very important to remember that dpmo and ppm may or may not be the same. A sigma value is a statistical term otherwise known as a standard deviation. The direct conversion between ppm and sigma (as in, not the six sigma conversion). Determining the standard deviation of a set of values helps a statistician or researcher to determine if the data set is significantly different than a control set. Welcome to getting started six sigma conversion tables. Use the conversion chart to determine dpmo and sigma level. I'm catherine macgyver, and today we're gonna understand how to use a sigma table. Convert 1 sigma to seconds (sgm to sec) with our conversion calculator and conversion tables. In the above table, we have assumed that the standard sigma shift of 1.5 is appropriate (the process sigma calculator allows you to specify another value), the data is normally distributed, and the process is stable. So, as is typical in engineering, we assume that our process errors are going operating under that assumption, the direct conversion between ppm and sigma is pretty straightforward.

Sigma Conversion Table: I'm catherine macgyver, and today we're gonna understand how to use a sigma table.

Source: Sigma Conversion Table

0 Comment:

Post a Comment